Your Guide to EN standards

Udgivet: 01/3-2020 | Læsetid: 11m 32s

Knowledge about PPE (Personal Protective Equipment)

Head Protection

Hearing Protection

Eye Protection

Respiratory Protection

Hand and Arm Protection

Fallprotection

Protective Clothing

Safety Footwear

Regulation EU 2016/425

Anyone who manufactures, imports or - in his own name - markets personal protective equipment should familiarize himself with the Personal Protective Equipment Regulation.

Regulation Header

"European-Parliament and Council regulation (EU) 2016/425 9th of March 2016 regarding personal protective equipment and repealing Council Directive 89/686/EEC".

Entry into force date and transitional arrangement

From 21st of April 2018, Directive 89/686 / EEC was repealed and replaced by a new PPE Regulation (EU 2016/425) on personal protective equipment.

The Regulation provides for a transitional period of one year. Thus, personal protective equipment designed and manufactured in accordance with Directive 89/686/EEC can still be marketed until 21st of April 2019.

What is covered by the regulation?

Personal protective equipment is defined as equipment designed and manufactured to be worn or held by a person to protect against one or more risks to that person's health or safety, as well as interchangeable parts of equipment and equipment connection systems.

Exceptions

The Regulation does not apply to personal protective equipment which are:

(a) specially designed for use by armed forces or to maintain law and order

(b) designed for self-defense purposes, with the exception of personal protective equipment intended for sporting activities;

(c) designed for private use to protect against:

- non-extreme weather conditions

- moisture and water during washing

(d) intended exclusively for use on seagoing ships or aircraft subject to the relevant international treaties in force in the Member States;

(e) intended for head, face or eye protection, for users covered by Regulation No 22 of the United Nations Economic Commission for Europe on uniform regulations on the approval of helmets for drivers and passengers on motorcycles and mopeds.

Essential requirements

In order to be able to CE mark personal protective equipment, the manufacturer or his representative in the EU must ensure that the products comply with the essential health and safety requirements set out in Annex II of the Regulation.

The manufacturer must carry out a risk assessment to identify the risks associated with his personal protective equipment. The manufacturer then designs and manufactures it, taking this assessment into account.

There are a number of general requirements, such as for design principles, levels of protection, comfort, efficiency and instructions for use, as well as common requirements for several species and types of personal protective equipment. Finally, a number of specific requirements regarding specific risks, such as mechanical blows, falls, drowning, noise, heat, cold, electric shock, radiation, etc. are listed.

Conformity Assessment Procedure

The obligations depend on how the personal protective equipment is to be classified according to the risk categories in Annex I to the Regulation and according to increasing risk categories 1, 2 and 3, as described in Article 19 of the Regulation.

Category 1 products are typically the products that must protect against minimal risks such as superficial incisions, contact with inactive detergents, contact with hot surfaces or protect from exposure to sunlight. Typically, consumer protection products are listed here.

Category 2 products are subject to risks other than those listed in Category I and III. Typically, products for both consumers and professional use are listed here.

Category 3 products include risks that can have very serious consequences, such as death or irreparable health damage, related to substances and mixtures that are hazardous to health, products intended to protect against atmospheres with oxygen deficiency, harmful radiation, very hot and cold environments, falls from heights , drowning, cuts from chainsaws, significant noise. Typically, professional protective equipment is listed here.

Presumption of conformity

Personal protective equipment complying with the harmonized standards or parts thereof is presumed to comply with the essential health and safety requirements set out in Annex II covered by these standards or parts thereof.

Technical documentation

The technical documentation must contain a description of the means used by the manufacturer to ensure that the protective equipment in question complies with the applicable essential health and safety requirements referred to in Article 5 and set out in Annex II. Including description of the protective device, risk assessment, design and production drawings, references to the harmonized standards, test reports, instructions for use, etc.

Marking

The CE marking must be affixed visibly, legibly and so that it cannot be erased, on the personal protective equipment concerned. If the protective device concerned is such that it is not possible or inappropriate, the CE marking shall be affixed to the packaging and accompanying documents. For category 3 personal protective equipment, the CE marking shall be followed by the identification number of the notified body participating in the procedure.

Notified body

Certain products must be approved by a notified body. There is free choice whether it is a notified body in Denmark or in another country. You decide which authorized body you want to use based on the areas of expertise to which the body is authorized. Factors besides the authorization that may influence your choice may be, for example, language, price, delivery time, etc. Not all disciplines are represented by notified bodies in Denmark. If it applies to your product, you must search in other countries.

You can find the list of notified bodies in Denmark here.

If you have any doubts about which authorized body you should use, you are welcome to contact our Information Center, tel. +45 39966140.

Responsible authority

Safety Agency

The text is written with full editorial freedom to select relevant information from and about the directive in order to provide a brief introduction to the directive in terms of purpose, scope and terms. In connection with the CE marking, we also recommend that you refer to the full text of the directive, the relevant Danish legislation and relevant standards.

Head Protection

| EN Standard | Text |

|---|---|

| EN 397:2012 | Industrial safety helmets, Manufacturer's name or bookmark, Year of manufacture and quarter, possibly month, Helmet type, stated on both helmet shell and upholstery, Size in centimeters, indicated on both helmet shell and upholstery, EN 397 (standard number) The instructions for use must be included which describe how long the helmet may be used after being put into service / from the date of production. May be approved as follows: Electrically insulating up to 440V - only helmets without ventilation LD approved - Tested against side impact MM - Tested against metal splashes. |

| EN50365:2003 | Chin strap (if fitted) Buckle must not open before load reaches 250N Electrically insulating up to 1000V |

| EN12492:2012 | Climbing helmet Chin strap (if fitted) Buckle must not open before load reaches 500N |

| EN812:2012 | Hard work hat - Do not use where helmet use is required |

| EN443:2008 | Fireman's helmet |

Hearing Protection

| EN Standard | Text |

| EN352-1: 2003 | Cup-type hearing protectors |

| EN352-2: 2003 | Hearing protectors of the type of earbuds |

| EN352-3: 2003 | Hearing protectors of the type that can be mounted |

EN352-4: 2020 | Level dependent earmuffs |

EN352-5: 2020 | Active noise reduction earmuffs |

| EN458:2016 | Recommendations on selection, use, |

The HML method describes the following protection: These describe how much hearing protection protector in hearing protection must be offered by the employer at 80dB and MUST be used at 85dB |

Eye Protection

| EN Standard | Text |

| EN165:2005 | Personal eye protection - withdrawn and replaced by DS/EN ISO 4007:2018 |

| EN166:2002 | Eye protection general requirements |

| EN167:2002 | Eye protection optical test methods |

| EN168:2002 | Eye protection not optical testing methods |

| EN169:2002 | Eye protection - Filters for welding and related processes - Transmission properties and recommended use. |

| EN170:2002 | Eye protection - Ultraviolet filters - Requirements for transmission characteristics and recommended use. |

| EN171:2002 | Eye protection - Infrared filters - Requirements for transmission characteristics and recommended use. |

| EN172:2002 | Eye protection - Sun protection filters for business use |

| EN174:2002 | Eye protection - Ski goggles for alpine skiing |

| EN175:2002 | Personal protective equipment - Equipment for eye and face protection during welding and similar processes. |

| EN207:2002 | Eye protection - Filters and eye protection against laser radiation. |

| EN209:2002 | Eye protection against laser radiation during adjustment work. |

| EN379:2002 | Eye protection - Specifications for welding glass with variable light transmission and welding glass with dual light transmission. |

| EN1731:2007 | Eye protection and face protection of the net type for professional and non-professional use against mechanical hazards and/or heat. |

| Eye protection must be worn in any work where there is a risk of damaging the eyes. Eye and face protection can be divided into the following categories: |

|

| Frame Glasses Ordinary glasses types with lenses of impact resistant polycarbonate or Chemical resistant acetate. |

|

| Closed glasses - goggles Closed glasses that close to the face. Has lenses of impact resistant polycarbonate or chemical resistant acetate. |

|

| Face shields and visors Face screens and visors where the user's face must be protected from splashes, particles and heat - or during welding. |

|

| Eye protection integrated in respirators Full face mask for respiratory protection is an essential part of eye and face protection. |

|

| Safety glasses with strength Safety glasses are available with visual field for reading and precision work. Safety glasses can also be manufactured according to individual vision tests like ordinary glasses with approved safety glasses. |

|

Mecanical None S F B A K N | Strength Basic requirements Enhanced strength (12 m/s) Impact with low strength (45 m/s)* Impact with medium strength (120 m/s)* Impact with high strength (190 m/s)* Scratch resistance Fog resistance |

Areas of 3 4 5 8 9 | use Fluids (sprays or splashes) Big dust particles Gas and fine dust particles Arcs from hotwiring Melted metal and very hot subjects |

Optical 1 2 3 | class Permanent use Partial use Occational use |

Lens filtertype 2 2C el. 3 4 5 el. 6 1,7 til 7 | (protection) UV filter UV filter with good color reproduction Infrared filter Sunglare filter = welding filter, if no toning number |

Scale number 1.4 1.7 2 2.5 3.1 4.1 *amount of

| (toning) at sunglare filter* 58,1 – 80,0 % 43,2 – 58,1 % 29,1 – 43,2 % 17,8 – 29,1 % 8,0 – 17,8 % 3,0 – 8,0 % sunlight that is allowed through the lens to reach user eyes. |

| Lens Color | Choosing the lens type and color can be difficult. Here is an overview of application examples: |

| Clear | Indoor use and under normal outdoor lighting conditions |

| Grey | When needed to dim sunlight |

| Brown | When needed to dim sunlight |

| Bronze | When needed to dim sunlight |

| Yellow | Enhances contrasts |

| Blue | In dim or difficult lighting conditions. Enhances contrasts |

Orange | In dim or difficult lighting conditions. Enhances contrasts |

| Silver mirror | Reduces reflections, dims sunlight and reduces the transition between light and dark areas |

| Blue mirror | Reduces reflections, dims sunlight and reduces the transition between light and dark areas |

| Red mirror | Reduces reflections, dims sunlight and reduces the transition between light and dark areas |

| Green DIN 5 | For gas welding, cutting and brazing |

| Green DIN 3 | For easy cutting and soldering |

Lensmaterial Acetate

Polycarbonate |

Plastic material, especially suitable for working with chemicals and solvents Strong, tough and the material with the greatest mechanical impact strength |

Respiratory Protection

| EN Standard | Text |

| EN136:2004 | Full face masks - general requirements |

| EN140:2000 | Half masks - general requirements |

| EN143:2006 | Particle filters - general requirements |

| EN149:2009 | Filtering face masks against particles - general requirements |

| EN405:2009 | Filtering face masks against gasses/particles - general requirements |

| EN12941:2008 | Respiratory protection, motorised with helmet/hood - general requirements |

| EN12942:2008 | Respiratory protection with turbo unit - general requirements |

| EN14387:2008 | Gas filters and combination filters - general requirements |

| EN14594:2005 | Air supplied hood/visor |

Particle filters:

Class P1 has the lowest degree of excretion and therefore only protects to a limited extent from dust (solid particles). The filter must not be used if the limit value of the pollutant is below 5 mg / m3. Examples of dust types that the filter does not protect are asbestos fibers and quartz, metal and wood dust. Class P2 has a higher degree of excretion and therefore protects to a greater extent. It can be used against harmful and toxic dust, but not against radioactive dust, bacteria and viruses. These filters are available in two types, partly for use only against solid particles and partly for use against solid particles and liquid aerosols. Class P3 has the highest degree of excretion and protects as class P2 as well as against radioactive dust, bacteria and viruses. The filter is usually for use against both solid particles and liquid aerosols. Not all P3 filters are suitable for use in half masks. | |

Gas filters: Filter type A protects against vapors from organic solvents with a boiling point above 65 ° C, eg mineral turpentine, toluene, xylene and butyl acetate. A filters have brown color code. In order for the mask to be dense and functioning properly, it is important that the membranes are intact. It is therefore necessary to check this periodically and to replace defective membranes. | |

Types of respiratory protection: Filtrating short-time mask The masks must be labeled with the filter class as well as an R (reusable) for multiple use masks or NR (non reusable) for single use masks. Some masks are labeled with, for example, FFP2D. The D-mark (Dolomit test) means that the material has a particularly large dust capacity, so that the resistance only increases slowly. Masks with D-marking are suitable for multiple use.

Half mask: Mask covering the chin, mouth and nose. The mask is equipped with an inhalation valve, an exhalation valve and is for the application of filters. The masks can also be fitted with solid filters and must be labeled with the filter class as well as an R (reusable) for multi-use masks or NR (non reusable) for single use masks. Some masks are labeled with, for example, FFP2D. The D-mark (Dolomit test) means that the material has a particularly large dust capacity, so that the resistance only increases slowly. Masks with D-marking are suitable for multiple use. Full face mask: As the name says, the mask covers the entire face - chin, mouth, nose and eyes. The mask is equipped with an inhalation valve, an exhalation valve and interchangeable filters. Full face masks are also supplied for use with external air supply. | |

Turbo equipment: The turbo gear is combined with a full or half mask, hood or a body with a tight-fitting visor. Air supplied respiratory protection: The equipment is combined with a full- or half-mask, hood or a body with tight-fitting visor. | |

Choice of respiratory protection: When choosing a respirator, it is important to consider the following: What air pollution is this? - dust, fumes, gases, aerosols or a combination - and at what concentrations?

| |

What kind of freedom of sight and movement is wanted from the equipment?

|

Hand and Arm Protection

| EN Standard | Text | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| EN420:2009 | General requirements for protective gloves no requirments of testing, the manufacturer simply has to state that requirements are met. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

EN388:2016  | Protective gloves requirements for mechanical testing EN 388:2016

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

EN ISO374:2016 & EN ISO374-2:2014 | Protective gloves for protection against chemicals & micro organisms General requirements EN ISO374:2016 The standard classifies three types of gloves after protection level (A, B and C). EN ISO 374-2:2014 The gloves must pass the air or water penetration test and meet the established AQL inspection level. In an air penetration test, the interior of the glove is pressurized with air and the surface is checked for holes. In a water penetration test, the glove is filled with water and checked for the presence of water droplets on the outside after a specified period. AQL (Accepted Quality Level) is a quality assurance measure based on an ISO 2859-1 sampling procedure used by manufacturers to measure the likelihood of pinhole defects in a batch of gloves. An AQL of 1.5 accepts the statistical probability that the lot contains less than 1.5% faulty gloves.

EN 16523-1:2015 Test method for measuring the resistance of the materials used for the personal protective equipment in relation to the penetration of hazardous chemicals at the molecular level and during uninterrupted contact. The resulting value is the penetration time or the time it takes for the dangerous liquid or gas to come in contact with the skin. The glove is classified according to the performance level performance from 1 to 6. (see table at top right).

This standard lists 18 chemicals. The minimum penetration time for a type A glove is 30 minutes. (level 2) for 6 chemicals, for type B it is 30 min. for at least 3 chemicals, and for type C it is 10 min. (level 1) for at least 1 chemical on the list. TYPE A: Penetration time ≥ 30 minutes for least 6 chemicals from list. The pictogram for “chemical resistant” gloves must be accompanied by the code letters for the tested chemicals for type A and type B gloves. Type C gloves are without code letter.

PENETRATION TIME (PERMEATION) = The time it takes for a chemical to penetrate from the outside to the inside of the glove material. Penetration test shall be performed at 23 ° C ± 1 ° C. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

EN ISO374-4 and EN ISO374- 5 | EN ISO 374-4 EN ISO 374-5 Microorganisms are defined in the standard as bacteria, fungi or viruses. In order to be able to indicate resistance to bacteria and fungi, the glove must meet the requirements for the test of resistance to penetration in accordance with standard DS / EN 374-2: 2014. If the glove meets the requirements of the test according to ISO 16604: 2004 (method B), it indicates that it is resistant to viruses, and the word “VIRUS” can be added under the pictogram of biological hazard. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| EN407:2018

| EN 407

1 = lowest value | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| EN12477:2005 | EN 12477 This standard is based on a series of tests from a number of other standards. The standard specifies minimum requirements for the results of these tests, to be tested and approved as a welding glove according to EN 12477. The standards that are tested according to are: EN 388 mechanical impact, EN 407 heat and/or fire. EN 367 heat transfer, EN 702 contact heat and EN 348 spray of molten metal. Welding gloves are approved in two types. Type A and type B. The requirements for type A are higher than type B in relation to the standards mentioned in most areas. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| EN421:2010 | Protective gloves tested against ionizing and raiodactive contamination | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| EN511:2006

| Protective gloves tested against cold EN511

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| EN10819:2013

| Anti vabration protective gloves EN 10819ANTIVABRATION The glove is tested against vibrations and approved for antivibration. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| EN659:2008

| Protective Fire Gloves EN 659 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| EN381-4:1999

| Protectiv Glove for use with chainsaw EN 381-4PROTECTIVE GLOVES FOR USE BY USERS OF CHAINSAWS The glove is approved for work with a chainsaw. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| EN60903:2004

| Protective gloves for work under voltage EN 60903 Gloves approved in accordance with EN 60903 can be used for work tasks where there is a risk of electric shock. Before choosing the right glove for the task, it is important to know the tension to which one may be exposed:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

EN455-1:2002 EN455-2 EN455-3 EN455-4

| Protective gloves single use for medical use MEDICAL DISPOSABLE GLOVES, TIGHTNESS MEDICAL DISPOSABLE GLOVES, PHYSICAL ABILITIES MEDICAL DISPOSABLE GLOVES, BIOLOGICAL EVALUATION DETERMINATION OF SHELF LIFE The standard ensures that performance is not impaired during the storage period prior to use. Accelerated aging tests are performed on glove samples to determine shelf life so that the manufacturer can prove that their product can (typically) withstand up to 3 years and in some cases up to 5 years without losing their strength and protective properties. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

EN1149-1:2006

EN1149-2 | Protective gloves with electrostatic abilities ELECTROSTATIC ABILITIES: SURFACE RESISTANCE ELECTROSTATIC ABILITIES: THROUGHPUT RESISTANCE | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Glass/Fork

| Protective glove for handling food GLASS/FORKSymbol shows that the glove is approved for direct contact with food according to EU regulation 1935/2004. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Information

| INFORMATION BOOK If i is inserted in the pictogram it refers to that more information follows the product. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fallprotection

| EN Standard | Text |

| EN341 | Descend equipment |

| EN353-1 | Glide systems with a non elastic anchorline |

| EN353-3 | Glide systems with a flexible anchorline |

| EN354 | Lines |

| EN355 | Energy absorbers |

| EN358 | Support belts and support lines |

| EN360 | SRL's (Self Retracting Lifelines) etc. |

| EN361 | Harnesses |

| EN362 | Connectors (ec. carabiners) |

| EN363 | Fallprotection systems |

| EN364 | Test methods |

| EN365 | General requirements for user manuals, maintainance, periodic revision, repairs, marking and packing |

| EN795 | Anchoring devices, anchorpoints |

| EN813 | Bælte med siddegjorde |

| EN1496 | Lifting devices |

| EN1497 | Salvage harnesses |

| EN1498 | Salvage nooses |

| EN12841 | Rope Access equipment |

| EN Standards - International abbreviations | |

| EN | Godkendt iht. europæisk standard til brug i EU |

| ANSI | Approved for use in USA |

| NFPA | Approved for use in USA by firefighters |

| CSA | Approved for use in Canada |

| AS/NZS | Approved for use in Australia and New Zealand |

| EAC | Approved for use in some east european countries |

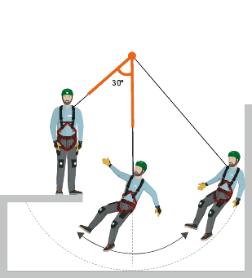

Pendulum swing

Unless the anchor point is just above the work site, be aware that in the event of a fall, you will swing back in the direction of the anchor point, just like a pendulum. Before planning the work, you must therefore take into account whether you are more than 30 degrees outside the anchor point and thus have an increased risk of hitting the pendulum swing.

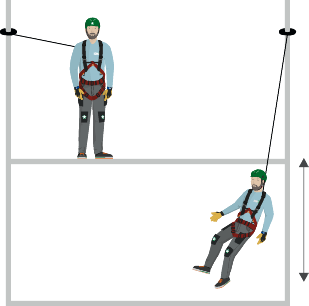

Fall factor 1

The anchor point is next to the D-ring in the back. Up to 4.5 meters ground clearance is usually required below the workplace.

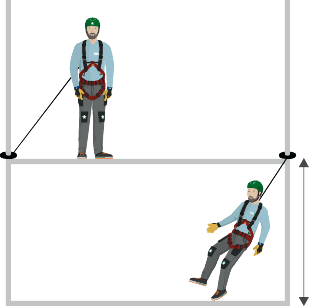

Fall factor 2

The anchor point is at foot height. Up to 6.5 meters ground clearance is usually required below the workplace.

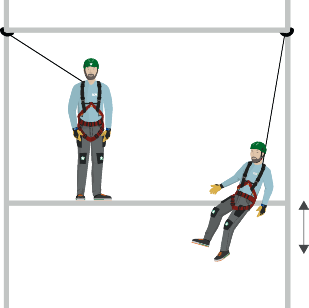

Fall factor 0

The anchor point is above the workplace. Up to 2.5 meters ground clearance is usually required below the workplace.

Protective Clothing

| EN Standard | Text |

| Cat 3 | Description of design for protective suits intended to protect against serious or fatal risks. The suits must be type approved. |

EN943-1:2019 EN943-2:2019  | Type 1 EN 943-1 & EN 943-2: Gas-tight protective suit is a protective coating against chemicals, liquid and gaseous, including liquid aerosols and solid particles. |

EN943-1:2019 | Type 2 EN 943-1: Non-gas tight protective suit, Suits that prevent dust, liquids and vapors from penetrating by internal overpressure. |

EN14605:2009 | Type 3&3B Liquid-tight suits: The suits are approved to withstand liquids under pressure, eg from hoses and nozzles. The suits must have welded seams. Penetration testing must be performed according to EN 369 to obtain knowledge about protection in relation to the individual chemicals, EN 14605. Type 3B protects against biologically contaminated particles, EN 14126. |

EN14605:2009 | Type 4&4B Spray-tight suits: The suits are approved for saturation of liquid that can condense on the suit. The suits must have welded seams. Penetration testing must be performed according to EN369 to obtain knowledge about protection in relation to the individual chemicals. |

EN ISO13982-1:2010 | Type 5&5B Protects against dangerous dust and particles. Type 5B Protects against biologically contaminated particles, EN 14126. |

EN13034:2009 | Type 6&6B Limited splash density. Protects if there is no risk of direct liquid spray on the suit. Type 6B protects against biologically contaminated particles, EN 14126. |

Protective Footwear

| EN Standard | Text |

| EN ISO20347 | Here you see symbol overview for EN20347: O1 Basic requirements are met, as well as oil-resistant outsole (ORO), closed tread, antistatic properties (A), and energy absorption in the tread (E). O2 as O1, as well as upper part resistant to water penetration and water absorption (WRU). O3 as O2, as well as an outsole (P) and outsole with wear pattern. |

| EN ISO20345:2004 | Here you see symbol overview for EN20345: Class 1 Footwear made of leather and the like. Class 2 Footwear made of rubber or polyurethane S1 Basic requirements are met, as well as oil-resistant outsole (ORO), closed tread, antistatic properties (A), and energy absorption in the tread (E). SB and the basic requirements: Clear height under toe cap after test: 14.5 mm .. (for sizes 43 and 44) in the shoe (21 mm. In free version) SB = Basic requirements met. S1 = SB + A + E + closed heel S5 = S4 + P + wear pattern on outsole |

| EN ISO17249:2004 | What was formerly EN345-2 is now: EN ISO 17249:2004 Protection when using a chainsaw |

| EN ISO17250:2004 | Fire-fighting protection. |

| EN13832 | Foot protection - Footwear for protection against chemicals |

| EN50321 | Electrically insulating footwear for use when working on low voltage installations |

| EN ISO20345:2004 | ESD Footwear All safety footwear approved according to static electricity discharge. Due to the construction and choice of materials, ESD footwear is designed to ensure the discharge of static electricity in a controlled manner. The limit values for the resistance in ESD footwear are between: 100KOhm and 35M Ohm. |